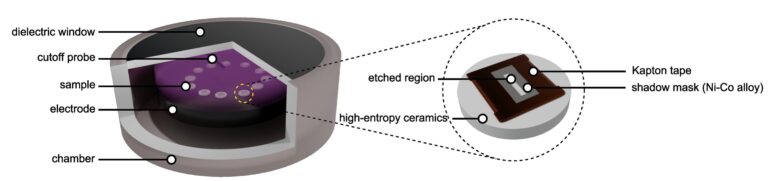

1 is a schematic diagram of plasma etching evaluation of ceramic materials. Credit: Korea Institute of Materials Science (Kims)

The research team has successfully developed a new composition and processing technology for clear plasma-resistant, highly entropy ceramics. This innovation is the world’s first and is designed to extend the life of internal components of semiconductor etch equipment and reduce contaminated particles during the semiconductor manufacturing process. This study is published in the Journal of Advanced Ceramics.

Ceramics account for more than 90% of the materials used in the internal components of semiconductor etch equipment. One of the main reasons is its superior plasma tolerance compared to other materials. Similar to the way a ship rusts when exposed to seawater, the plasma used during the etching process reacts continuously with the internal components of the equipment, leading to corrosion and contamination.

To address these issues, ceramics have been adopted as a selection material. However, as semiconductor integration levels increase, the etching process is carried out in increasingly demanding environments. This will replace traditional ceramic components more frequently, and negatively affect semiconductor productivity.

The researchers have moved away from the limitations of traditional ceramic materials such as Yttria (y₂o₃), alumina (al₂o₃), and yag (yttrium aluminum garnet) by designing new high-entropy ceramic compositions.

Using a sintering process of inorganic concentration bodies (high density solid materials), we have successfully developed transparent ceramics at a density of 99.9%. These dense ceramics are suitable for use in etching process equipment that require plasma resistance.

Additionally, the team analyzed changes in the crystal structure of elements, including high-entropy ceramics, and developed a transparent ceramic that can transmit visible and infrared rays by controlling the porosity.

Images of transparent plasma-resistant, highly entropy ceramics developed along with crystal structure models. Credit: Korea Institute of Materials Science (Kims)

High entropy ceramics are a type of ceramic material created by mixing five or more elements to form a single phase (a uniform structure) without generating impurities, unlike traditional materials. These ceramics exhibit unique properties such as high heat resistance, excellent wear resistance and low thermal conductivity, making them increasingly prominent as thermal barrier materials, catalysts and energy storage materials.

However, no studies on their plasma resistance have been conducted up until now. Recognizing this gap, the research team has successfully achieved the development of the world’s first plasma-resistant, highly entropy ceramic, focusing on this field.

In semiconductor processes, materials with low etch rates indicate less contaminating particles and more durable. The high-entropy transparent ceramic, developed by the research team, exhibited a very low etch rate, achieving just 1.13% compared to sapphire. Furthermore, compared to Its excellent plasma resistance, it demonstrated an etch rate of 8.25%, which confirms its excellent durability.

Kims senior researcher Ho Jin Ma said, “In semiconductor processes, plasma etching is dominated by the materials, components and equipment in the US and Japan, which account for more than 90% of the market, and domestic industries become foreign sources. I found it to be highly dependent.

“The results of this research show are the leading example of developing a material that has never been studied before, a highly entropy ceramic, to create world-class plasma-resistant materials using unique domestic technology. It is a progress in material self-sufficiency and component localization.”

This research was a collaboration between the Korean Institute of Materials Science (KIMS) and Professor Jungwoo Lee of Pusan National University.

Details: Yu-Bin Shin et al, Novel Clear High Entropy Sesquioxide Ceramics with High Physicochemical Plasma Etching Resistance, Journal of Advanced Ceramics (2024). doi:10.26599/jac.2024.9221013

Provided by the National Council on Science and Technology

Quote: New Transparent Ceramics Extend the Life of Semiconductor Etching Equipment (February 14, 2025) February 14, 2025 https://techxplore.com/news/2025-02-Transparent-ceramics-life- semuncuncor-echunting.htmll

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.