With recent advances in artificial intelligence-based visual identification, construction site monitoring provider Earthcam was keen to introduce these capabilities to its extensive camera network.

Now, as AI technology continues to become more sophisticated, the company is moving beyond safety-related visual AI detection to active monitoring of material delivery and installation.

“Material tracking (feature) has been in beta for a year. We just announced it at (Procore) Groundbreak,” explains Earthcam CEO Brian Curie. The system is trained on images from Earthcam’s countless field cameras, integrates with Procore and Autodesk software, and updates project progress based on scheduled tasks based on Earthcam material analysis.

Image provided by: Earthcam

Image provided by: Earthcam“We like to say we’re a software business, not a camera business,” Cury says. “We deliver equipment and materials to the site, send it to Procore, and use imagery to match schedules,” he explains.

When materials arrive on site, an alert is automatically generated and a photo is automatically attached. “So let’s say the HVAC ducts were delivered. Here’s a photo of them as delivered. What makes the difference is a true visual signal source.”

Image provided by: Earthcam

Image provided by: EarthcamCury believes the increased use of visual detection AI is one key way to compensate for deficiencies in current construction schedules.

“The schedule has been extended since the pandemic, and the industry is trying to get it back on track,” he says. “But people aren’t communicating. Electricians arrive with workers, but work on the studs hasn’t started yet, so even when work starts, they might not come for several weeks. So we , we moved to alerts and color-coding to keep things moving.”

Automatic color-coding of materials and tracking of installation progress is a highly requested feature, Cury said, and in recent years many properties have utilized Earthcam and other camera systems to monitor remote sites. For example, we use developers and developers. But manually scouring video footage to determine what work has been done is time-consuming and a natural fit for AI automation, he says.

Another unexpectedly popular feature uses visual AI to track the fullness of on-site dumpsters, helping to schedule quick removal of construction waste. “If the dumpsters are full on the weekends, there is a fire hazard,” Cury points out. “So with AI, we can tell if the bin is full or empty.”

Improving workplace safety with AI

While material and labor tracking uses cloud-based systems and a focus on broader software integration, Earthcam also continues to develop onboard camera AI processing for instant safety alerts.

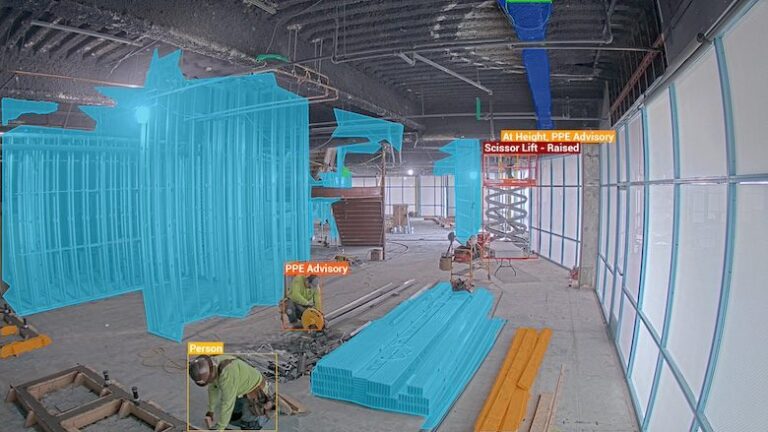

The company offers cameras with built-in AI analytics to tag safety violations such as lack of PPE, fall hazards, and unsafe use of equipment. In addition to pointing out common hazards such as spills or when someone gets too close to working equipment, visual AI can tag workers working at height and check if they are properly restrained. You can also rate it.

Image provided by: Earthcam

Image provided by: EarthcamWilliam Sharp, Earthcam’s vice president of product development, says edge detection for the work-at-height feature was a bit difficult to program. “We’ve gotten to the point where we can pick up (workers) on roofs, on scaffolding, on elevators. Height certification works there as well.”

This has been a challenge since these are stationary cameras positioned at odd angles, but Earthcam’s visual processing has gotten to the point where edge detection is fairly consistent regardless of complex visual geometry. I did, says Sharp. “I have been doing this for a long time. Every time we face new challenges, we have been able to solve each one. Because the challenges come one after another. We will continue to solve them .”