Canon Launches FPA-3030i6, a Semiconductor Exposure System for Small Wafers Equipped with Newly Developed Lenses and a Variety of Options to Meet Growing Demand for Power Devices

TOKYO, Sept. 24, 2024 – Canon Inc. today announced the launch of the i-line1 stepper FPA-3030i6, a new semiconductor lithography tool for processing wafers with a diameter of 8 inches (200 mm) or less.

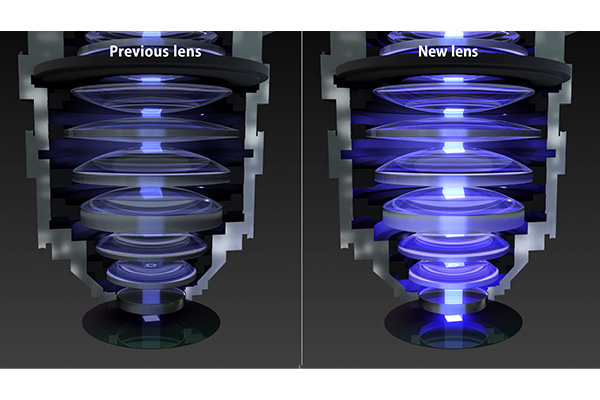

The FPA-3030i6 employs a newly developed projection lens that boasts high transmittance and durability, reducing lens aberration in high exposure processes and shortening exposure times to improve productivity.

The lenses are made of high-transmittance glass material, which reduces lens aberrations during exposure by more than 50%2 compared to conventional stepper models.3 The high transmittance allows for shorter exposure times while maintaining pattern fidelity, even at high exposure doses.

The improved lens transmittance also increases the exposure intensity, shortening the exposure time required for each step. With the FPA-3030i6, the standard productivity of 8-inch (200 mm) wafers has increased from 123 wafers per hour for the previous model to 130 wafers per hour.

In addition, the lenses are highly durable, reducing degradation of lens transmission over time, helping to maintain productivity throughout the life of the system.

The NA (numerical aperture) range has also been expanded from 0.45-0.63 in the previous model to 0.30-0.63. By reducing the NA, it is possible to select the optimal NA for each device layer.

In order to meet the manufacturing needs of various emerging semiconductor devices, such as high-output, high-efficiency green devices, we also accept orders for optional products such as wafer handling systems for special substrates.

The FPA-3030i6 is designed to support a wider range of device manufacturing with a range of process options available for silicon (Si) as well as compound semiconductor materials such as sapphire, silicon carbide (SiC), gallium nitride (GaN) and gallium arsenide (GaAs) substrates.

Canon offers wafer supply options that allow handling of substrates from 2 inches (50 mm) to 8 inches (200 mm) in diameter, including handling of thick, thin and warped substrates.

1

Semiconductor exposure equipment using an i-line (mercury lamp, wavelength 365 nm) light source

1 nm (nanometer) = 1 billionth of a meter

2

Under Canon standard exposure conditions

3

FPA-3030i5a (released in March 2021)

4

8 inch (200 mm) wafer