At the heart of every electronic device is the semiconductor chip. These small circuits will improve the fuel efficiency of your car, allow computers to process and store data, allowing you to download the latest apps on your phone. However, the process of manufacturing semiconductor chips is difficult and the time is ripe for improvement. One small mistake costs millions, but advanced technology can help eliminate defects in manufacturing and transform the entire industry.

UCF will support the development of this technology through a new Regional Studies Hub, led by the University of Florida. The goal is to optimize semiconductor manufacturing using virtual representations of physical objects or processes. The Florida/Caribbean hub is one of the seven research hubs in the United States, making up the Manufacturing USA Institute, known as Smart USA, which was awarded a $285 million award earlier this year by the Biden administration.

The funding was a very competitive result of the US Department of Commerce’s Chip Manufacturing US Institute Competition, which selected the Smart USA proposal from dozens of entries. Smart stands for twin semiconductor manufacturing and advanced research, led by Semiconductor Research Corporation.

“The focus of this hub will be digital twins,” said Reza Abdolvand, chairman of the Bureau of Electrical and Computer Engineering, who co-led with Grace Bochenek ’98phd, executive director of the Pegasus Research Institute and director of simulation and training. “The goal is to be able to virtualize the manufacturing process accurately and find out what goes wrong before starting a costly and time-consuming manufacturing process.”

Semiconductor manufacturing problems

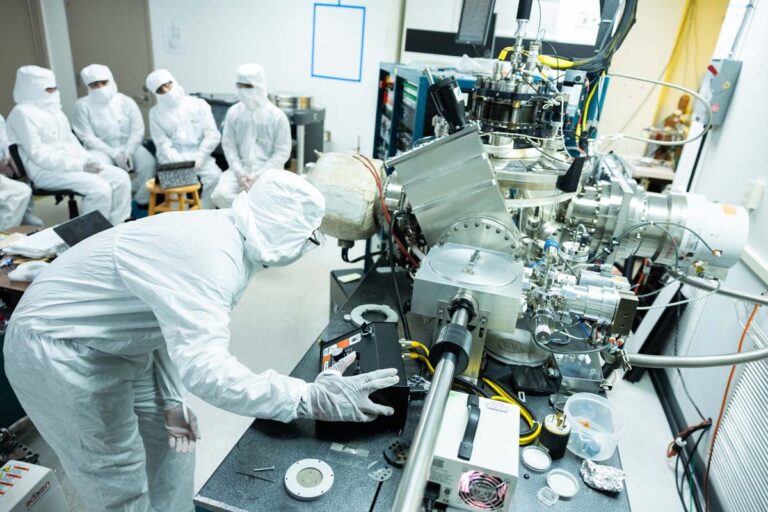

Semiconductor chips are not easy. They are manufactured in a massive facility called Semiconductor Manufacturing Plants, which are made up of highly controlled environments called Cleanrooms. Here, the air is constantly filtered to remove small particles that can cause defects in the final product. Most chips are made of silicon wafers that are more brittle than glass, and the process of converting these silicon substrates into semiconductor chips is long and complicated. It takes hundreds of steps and up to six months to generate one silicon wafer from start to finish.

“The mistakes in this process are very expensive and can be made in many steps,” Abdolvand said. “In a design, for example, if the design is broken, the final product can be defective and you can lose billions of dollars.”

Now, the industry can use modeling and simulation in its design process. This allows you to better predict whether the final product will function as intended. However, this technology has not kept up to its manufacturing process.

“Manufacturing is basically trial and error until you’re satisfied with what you see,” says Abdulband. “The hope is to extend the concept of modeling to what tools can do on the board. What would you do if you could simulate what tools would do before they happen?”

Tools used in manufacturing processes can become obsolete and can be deprecated very quickly. This also poses challenges for the industry, specifically increasing the repetitive costs of manufacturing modeling.

The role of UCF in the research hub

Advances in artificial intelligence and machine learning have enabled the development of realistic models that can solve the challenges of the semiconductor industry. Use AI-enabled digital twins to mimic manufacturing processes, predict which errors can be created before tech companies occur, allowing them to save both time and money.

Abdolvand and Bochenek are leading university responsibilities. Together, ECE and IST researchers collect, collect, analyze and interpret data that can be used to create digital twins.

“We are excited about this partnership and UCF’s contribution to Smart USA’s efforts to achieve national security goals through innovative digital transformation,” says Bochenek. “This region is important in ensuring the US’s global competitive advantage in manufacturing this semiconductor chip.”

Bringing semiconductor manufacturing to the US is an important goal for the lab and is not only a dominant one in the global market, but also more cost-effective.

“The biggest companies in charge of the semiconductor business are in the US, where they design here, but the manufacturing is outside the US,” says Abdolvand. “The plan is that if we can reduce manufacturing costs with digital twinning, if we can reduce manufacturing costs in the US, if we can do manufacturing in the US, and it’s still very cost-competitive.”